CONTACT PERSON

Marketing :

General Manager :

Manufacturing Director :

Mold Number:16033

Prepared by:Leo Tang

Date Prepared:July 5th 2019

Version:Rev.1

Analysis Purpose |

Validate potential problem after the part and mold design Check the fill balance pattern, weld line, air traps, and predict the needed clamp force and injection pressure, warpage. |

Input Model Description |

The runner system is simulated as the mold design. |

Result Required |

Filling result Warpage result |

Actual of cavities |

1+1 |

Number of cavity analysis |

1+1 |

Part Material |

PC+ABS |

Type of analyses |

Flow + Warp |

■ The material datas are from supplier is in moldflow database and shown in the pictures below

Material Property |

|||

PC+ABS (Bayblend FR1514 from Covestro) |

Melt Temperature Range (℃) |

250~280 |

|

Solid Density (g/cm3) |

1.17 |

Mold Temperature Range (℃) |

60~80 |

Maximum Shear Rate (1/s) |

50000 |

Ejection Temperature (℃) |

135 |

Maximum Shear Stress (MPa) |

0.4 |

Absolute Maximum Melt Temperature (℃) |

320 |

MFR (g/10min) ( ℃/ Kg) |

/ |

Recommended Melt Temperature (℃) |

260 |

Filler |

Unfilled |

Recommended Mold Temperature (℃) |

70 |

| Part Details and Tool Description | |

Part Name |

Bottom cover & Top cover_hard part |

CAD File / Version/ Date |

16033_nrgkick_dsgn_asm_190627 /stp |

Part Volume |

207 (1*1) cm^3 |

Nominal Wall Thickness |

No uniform |

Tool Description |

1+1 Cavities |

Injection machine Tonnage |

/ |

| Process Setup | |

Material |

PC+ABS (Bayblend FR1514 from Covestro) |

Injection time |

2.5 s |

Material temp |

260 [deg.c] |

Mold temp |

70 [deg.c] |

Velocity/Pressure Transfer (% volume) |

98 % |

Packing Pressure/Time |

80% filling pressure /8 s, 60% filling pressure /4 s |

Project Area |

367 (1+1 ) cm^2 |

This above plot used different color to show the thickness of this part.

We can see that: the average thickness of this part isn’t uniform.

Total part weight = 237 g (1+1 ) , the cold runners weight = 34 g

This above plot used different color to show the thickness of this part.

We can see that: the average thickness of this part isn’t uniform.

Total part weight = 237 g (1+1 ) , the cold runners weight = 34 g

Gate Location and size

■ The mold is the cold runner and point gate.

■ The runner layout was based on the 3D drawing.

Fill time (Animate & Contour)

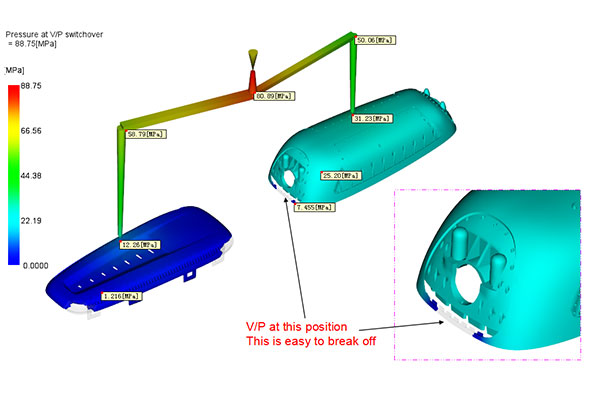

Pressure at the V/P switchover

Injection pressure

Clamp Force

Weld lines

Air Traps

Time to freeze

Volumetric shrinkage at ejection

Deflection

Conclusions and suggestions

From the above analysis

■ The cycle time is about: 2.5 (filling) + 50.0 (cooling + packing ) + 16.0 (open & eject) = 68.5 sec

■ This part will not have filling problem due to the pressure are within the moldflow recommend range.

■ Visible weld lines were expected appear at this part. (refer page 15~16)

■ Most of the air trapped appear at the edge of part and the tip of ribs that is easy to vent, some serious air traps appear on the surface. (refer page 17~18)

■ Visible sink mark may appear at the surface of part. (refer page 20)

■ This part have large uneven shrinkage at the X, Y, Z deflection, the different volumetric shrinkage (different wall thickness) result in the defect.

Copyright © 2018 Euromicron Mould Engineering Limited | All Rights Reserved