CONTACT PERSON

Marketing :

General Manager :

Manufacturing Director :

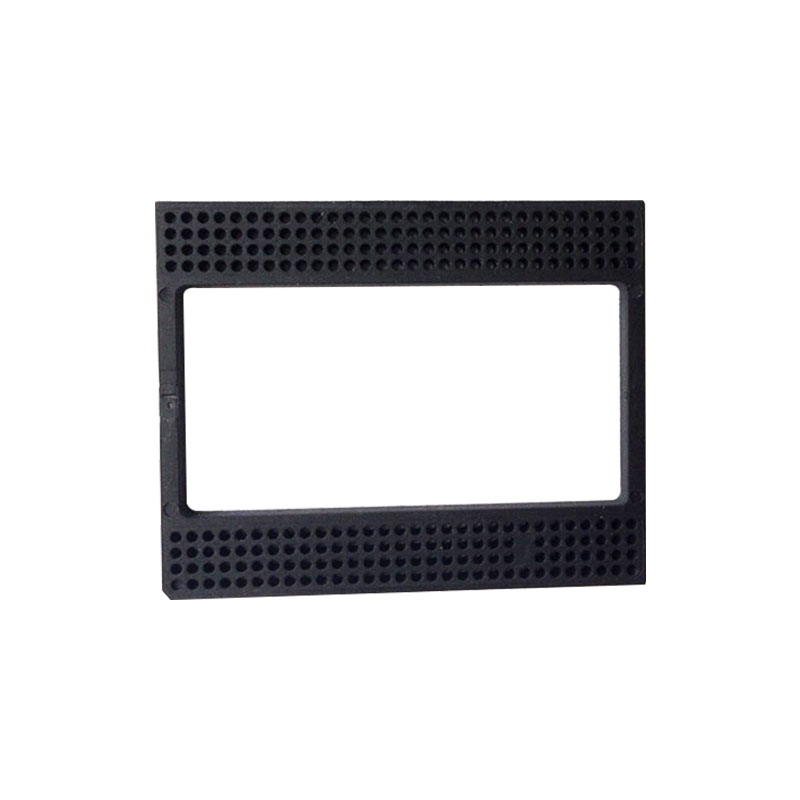

| Part Name: | Electronic connector |

| Part size: | 18*15*3mm |

| Raw Material: | NYLON+30%GF |

| Color: | RAL9005,Black |

| Mould Cavity No.: | 16+16 |

| Injection gate: | Cold runner |

| Surface finished: | Polishing #600 |

| Core &Cavity steel: | 1.2344, hardness 48~52HRC |

| Mold component standard: | DME or equivalent |

| Injection machine size: | 120T |

| Cycle time: | 18S |

| Mold life: | 300000 shots |

| Customer: | AEC |

| Export: | USA |

There are many small pin holes on part. Hole’s diameter is 0.6mm with 2.2mm distance of each. Dimension tolerance should be within +/-0.01mm. Mold design-We will make this mold with 2+2cavity, cold runner in to banana gate. To make parts leave on core side, parting line should be on top. And all pin holes location need to be inserted. Because the hole diameter and distance need to keep in strict tolerance. Separated insert make it easy to replace. Need to pay high attention to electrode making and EDM process. We made whole electrode include all pin holes position, then checked by CMM machine, until shown it was made in proper dimension, took to Mirror EDM manufacture.

Injection-Any mismatch or flash in switch(female half) hole would cause male half pin bend, so this request holding pressure not too high. but also guarantee not cause sink mark on outside surface. Although the part and mold is small, enough cooling line still necessary. Because the part quantity in demand is one million each month, we need to cut down cycle time as much as possible. So that we can save production cost.

Copyright © 2018 Euromicron Mould Engineering Limited | All Rights Reserved