CONTACT PERSON

Marketing :

General Manager :

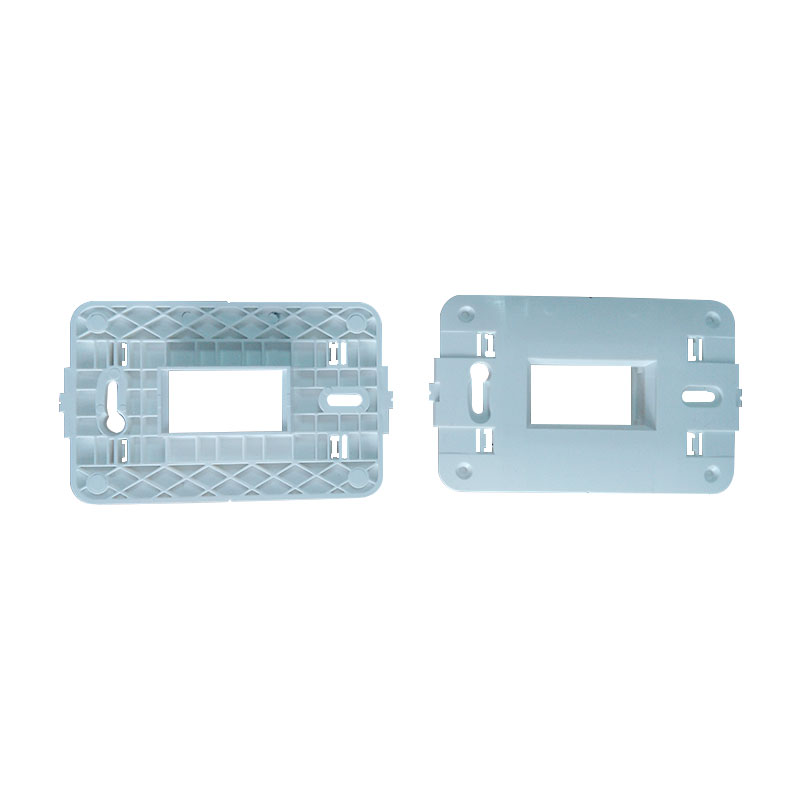

| Part Name: | switch |

| Part size: | 92.8*61.2*8.6mm |

| Raw Material: | ABS |

| Color: | RAL9010,White |

| Mould Cavity No.: | 1*4 |

| Injection gate: | Cold runner with sub gate |

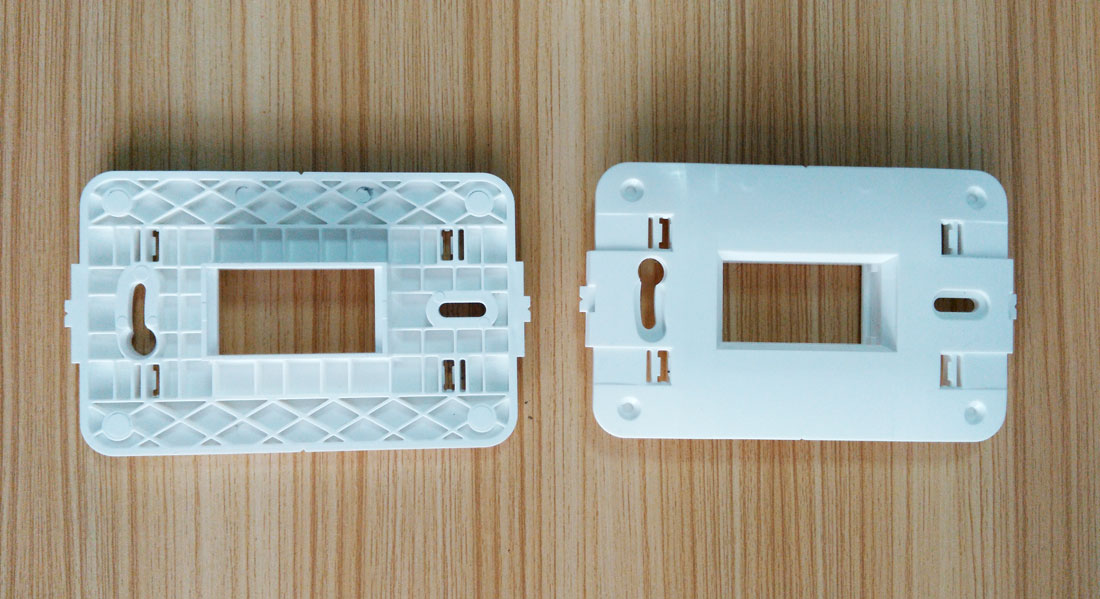

| Surface finished: | Polishing #600 |

| Core &Cavity steel: | M310,hardness 52~55HRC |

| Mold component standard: | DME or equivalent |

| Injection machine size: | 250T |

| Cycle time: | 35S |

| Mold life: | 300000 shots |

| Customer: | Siemens |

| Export: | Uruguay |

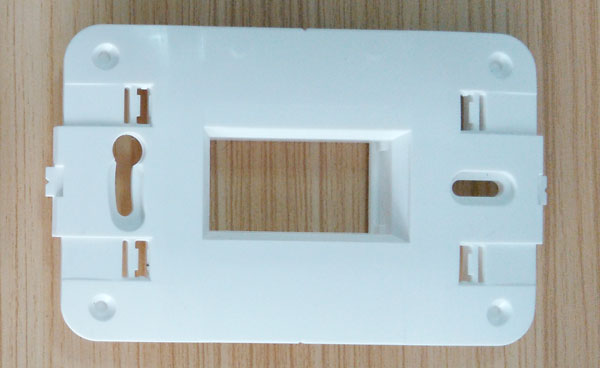

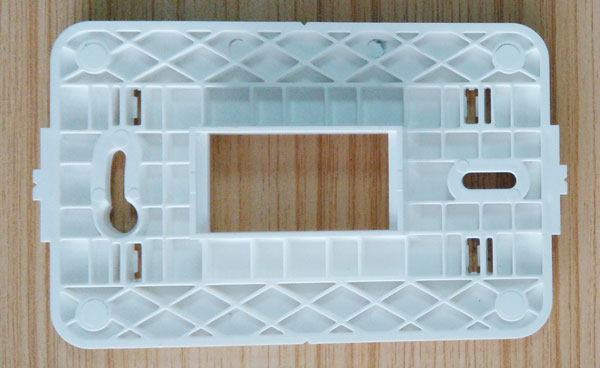

We carried out first trial shot on 35th day,twice trial shots for samples production,and finished whole project in 45days.Manufacture schedule,samples delivery and mold shipment date ran as planing,within customer’s request. Due to many thin and high side ribs,part stick on core side tightly.Mold need smooth polishing and need enough ejection pins and as big as possible.Sink mark problem on surface easily to cause,due the part thickness is too thick and not equal,we solved it by adjusting injection parameter.Four hooks distance need to be molding in high precision location,Because they will assemble to bottom shelf.To make it work well,we cut material at first trial shot.After checking first samples,made correction to mold.So that the secondary samples met assembly requirement.

Another problem we met on first trial shot was the ribs short shot.Because they were very thin and high,plastic filling easily to get cold when injection.Later we had a discussion,decided to change the side gate to two sub gates,change core cooling water to hot oil,100℃,and add injection pressure,so that filling time shorten a lot,finally we got excellent part. This experience also can apply to similar product with thin and high ribs.

Copyright © 2018 Euromicron Mould Engineering Limited | All Rights Reserved